News

Why Nigeria’s Power Grid Keeps Collapsing

Over an 18-year period, beginning from 2000, Nigeria’s electricity grid incredibly collapsed both partially or totally for 546 times. This collapse frequency is due majorly to the lack of a functional and reliable SCADA system that usually perceives disturbances and employs mitigating actions.

SCADA is the acronym for Supervisory, Control and Data Acquisition. It is a technology that acquires real time data from field equipment for the purpose of supervision, control and analysis of power systems and associated field elements. The control centre takes advantage of acquired data for informed and prompt decision making. When SCADA is fused with an Energy Management System (EMS), the system further enjoys benefits like outage planning, load forecast, contingency analysis, generation Unit Scheduling and commitment, market settlements, etc. The SCADA/EMS may therefore be considered the Power System’s ‘brain’ responsible for the efficient management and operation of interconnected systems within the Grid.

An electric power grid is a network of interconnected power systems for delivering power from producers to consumers. The collapse of the grid means loss of power supply across the environments/customers that the grid supplies. This is otherwise referred to as voltage collapse. Grid collapse is an unacceptable situation that warrants setting up of investigative panels whose findings ensure recommendations of possible solutions meant to avoid future occurrences. However, this is not the case with Nigeria’s grid. The grid collapses have been indiscriminate.

The existing SCADA/EMS is a proprietary Energy Management System by SIEMENS with proprietary database and inter- application messaging system. This system is vendor lock-in and its deployment was forklift (all in one); hence, TCN is compelled to buy all the EMS applications and equipment from this same vendor. This has circumscribed TCN’s ability to upgrade, modify or change packages to suit the realities of the present day market environment. Although the accompanying packages could meet the then demands of an energy market, modules like the Automated Meter Reader developed in-house by TCN or procured for certain functions from vendors rather than SIEMENS, cannot be integrated into this system because of the system’s proprietary nature.

It is even more worrisome that substations built, equipped and automated by vendors like ABB, NARI, GE, etc. cannot be easily integrated into this system without contracting the integration process out to SIEMENS or hiring the extremely special skills of experts who understand both systems. This is due solely to the lock-in nature of the existing system. The unfriendly nature of this deployed system has therefore annulled the integration objective and consequently hampered expansion and reliability.

The current TCN SCADA/EMS has centralized data aggregation centres at NCC Osogbo and SNCC Shiroro. The system consists of various packages like fault analyzers, data historian, power flow analyzer, contingency analyzer, etc. These various packages are aimed to work in harmony to achieve the key objectives of real time supervision and control of the power system for stability and security as well as data acquisition for system analysis and planning. However, these very appealing objectives are rarely achieved due to the limitations in communication infrastructure, substation automation, flexibility of the existing SCADA/EMS and user proficiency.

The dream for a desired and successful SCADA/EMS implementation begins with a reliable procurement process. To accomplish this, a solution-based procurement process which encompasses equipment procurement as well as all the factors that relate with the system to ensure that the desired objectives are met before the project close out should be adopted. This procurement process will recognize and correct the challenges that have plagued the current SCADA/EMS.

While many important requirements must be developed, perhaps one of the earliest to be considered is communications capability and required functionality. While specific features can be scaled to meet future needs and growth, available communications bandwidth needed to support any supplementary features should be taken into consideration upfront. Delivering communication services to operational applications requires not just implementing a suitable telecommunication infrastructure with adequate capacity but also with a high degree of reliability and security. The network must cover all service access points in power stations, control and monitoring platforms and must assure access to and from the technical offices. When very well designed and implemented, other applications like physical access control, video surveillance and metering can leverage the network’s robustness and reliability. Moreover, existing legacy systems like radios, antennas, RTUs, fibre and cabling can also be leveraged in order to maximize investment return and reduce upfront costs.

Further on, with about $65 million available for the SCADA project, TCN must automate analogue transmission stations ahead of the procurement process. Likewise, TCN should adopt a modular system of SCADA deployment, a strategy that can afford them the luxury to replace modules of the SCADA with desired ones, upgrade such modules, modify them or integrate in house developed applications as well as afford them the ability to tweak the SCADA to suit the realities of the Nigerian electricity market. The modules can be deployed separately and from varying vendors but must be interoperable for easy and quick integration with other modules of the system. This will solve the non-flexible nature of the current system and also eliminate the challenges encountered while dealing with proprietary systems.

Interestingly, by working with an outside engineering team well versed in the latest technologies (consultants), TCN can reduce complexities and make SCADA a reality. Experienced engineering teams familiar with the latest hardware and software components, as well as the potential challenges with integrating legacy equipment, can help control overall project costs and timing. This implies that TCN should employ the expertise of a consultant vast enough to support the project.

Also, the training of younger and ambitious engineers should not be neglected. This training can be captured in the procurement process such that there is knowledge transfer. These younger/ambitious engineers are assigned the desired EMS modules while working with prospective vendors as subject matter trainees. When very well trained, the said engineers will develop into subject matter experts and will be responsible for the design and prototyping of operational procedures in line with the grid code and operational procedures into the SCADA/EMS system. They will also be responsible for the training and day to day support of the user department staff.

In order to be abreast with the technology to come, the subject matter trainees should be supported with good knowledge of the power system and what is to come so that if possible, they decide the best way possible for modules to be implemented and prototyped.

Generally, the training of staff cannot be overemphasized. The future and maintenance of the system onus lies with the company’s staff, therefore if the system must be sustained, adequate training must be made available to maintenance and user department staff.

-

News4 days ago

News4 days agoAPC National Chairman: Moves To Oust Ganduje Put Presidency In Quandary

-

News3 days ago

News3 days agoOsun RAAMP Opens Bid For Road Constructions Statewide

-

News4 days ago

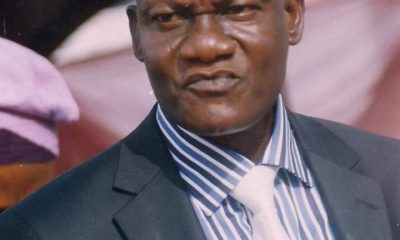

News4 days agoComrade Joseph Sangosanya dies at 67

-

Opinion3 days ago

Opinion3 days agoRegulatory Commission Must Wakeup From Slumber To Rescue EKEDC From The Shackles Of Dere Otubu By ADAPHAI